Renee Major, Central Supply & Lab Tracking (CSLT) Supervisor, positively glows when she talks about her staff.

“They work hard. They take pride in what they do,” she said. “People don’t understand the dedication and concern that goes into their responsibility. Ultimately, if the dental college doesn’t have supplies, things just don’t work.”

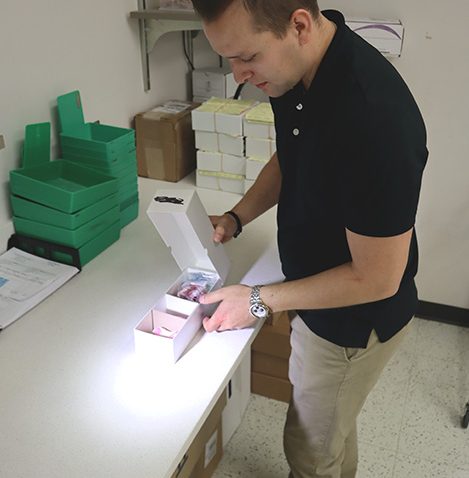

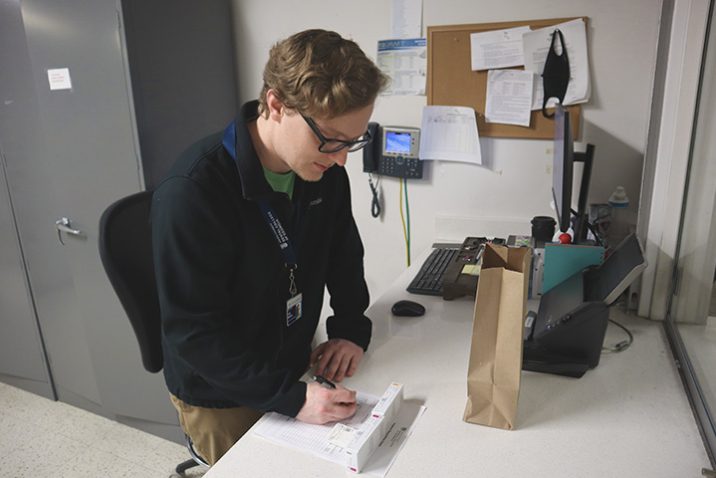

Major has major numbers to support her team’s essential role. CSLT’s inventory includes 937 different items that they keep in stock, in addition to the inventory used for to support specific clinics and the specialty items ordered as needed. Last year, CSLT ordered 282,920 items, received and verified 262,770 items, and organized, stocked, and distributed them – everything from elastomeric respirators, Hemodent, blood ID kits, to lidocaine.

CSLT averages more than 1,000 products per day to receive, verify, inventory and store for accurate and rapid distribution, all with a current team of only a few people: Angela McDowell, Tyler McNeely, Shana Middleton and Cory Morris, office specialists; and Serena Small, office associate.

CSLT averages more than 1,000 products per day to receive, verify, inventory and store for accurate and rapid distribution, all with a current team of only a few people: Angela McDowell, Tyler McNeely, Shana Middleton and Cory Morris, office specialists; and Serena Small, office associate.

“We have to be very proactive in forecasting what the DCG will need in the future. If we know, historically, that we have had trouble getting a product from the manufacturers or that a product is likely to be delayed by U.S. Customs, we build those predictions into our planning,” Major said.

Often, the team is engaged in complicated problem-solving to account for manufacturing delays, shipping interruptions, materials shortages and corporate production decisions.

“Right now, companies are looking for savings and they are cutting nonproductive lines,” said Robert Paist, Director of DCG Clinical Operations. “We work with the Instrument & Continuity Committee to source new products and suppliers when these situations arise. Our goal is the have everything stocked identically in pre-clinical training so that when students move to clinical experiences there is a seamless transition.”

Darrell Gentry, Associate Dean for Business and Finance, described the department as being as critical to the DCG as the heart is to the human body.

“On a daily basis, the employees are pumping supplies throughout our clinical operation similar to how the heart pumps blood through the body for survival,” Gentry said. “It’s hard to imagine what patient care would look like without their essential functions. Robert Paist and his whole team do an excellent job.”

Even though they’re working at the top of their game – forecasting as far in advance as they can and constantly communicating with vendors – sometimes the team has to get creative.

“During COVID, we had to find everything the DCG needed to keep things going. We had to think outside the box, and we came through with those challenges,” Major said.

The team found a distillery in Texas that shifted to manufacturing hand sanitizer during the pandemic. Whereas they would normally have been able to stock pump bottles of the desperately needed disinfectant, they had to order gallon jugs, recycle the old pump bottles, print new labels and refill them as needed.

“We did that for a long time to be able to stock just hand sanitizer,” Major said. And they also had to source personal protective equipment, thermometers, lab coats, shoe covers, bouffant caps, surgical caps and dozens of other products that were in high demand and low supply.

More recently, Dentsply Sirona discontinued a whole line of TruByte Products, including wax, denture materials and more.

“So, we had to find a new source that can meet comparable quality standards and needed quantities,” Paist said.

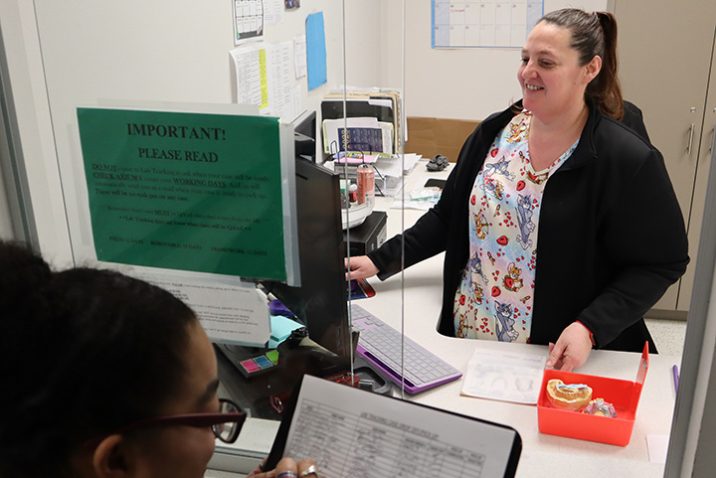

In addition to supply chain management, the team is also provides lab tracking. Last year they processed 5,112 lab cases, at an average of 426 per month and 21 per day. The team manages the acquisition and processing, including processing payments, clinical delivery and pickup, lab delivery, Axium recordkeeping and more.

Paist said the employees in CSLT are self-motivated and detail oriented to succeed in an ever-changing supply landscape of global networks. “They also handle a lot of things that are very valuable, so they have to be people of integrity,” he said.

“This job is fast paced with a lot of variables,” Major said. “It’s always moving. And we pull together as a team. We’ve been challenged, but our organizational skills and intelligence have carried us through.”

Augusta University

Augusta University